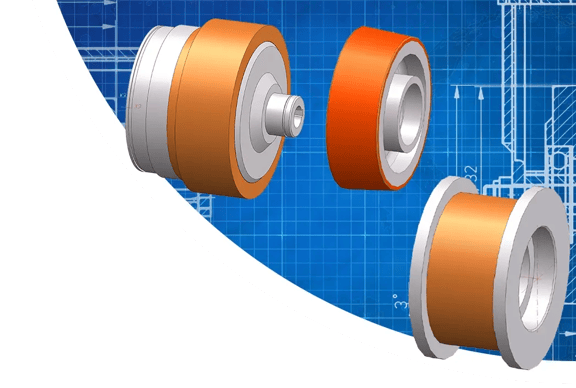

Individual coatings with Vulkollan® or polyurethane

With our individual coatings made of Vulkollan® or polyurethane, which we can produce in different Shore hardnesses, we can meet your individual customer requirements and find the right solution for your project.

Ask us specifically for an individual coating, we will be happy to help you.

New Coating of existing Customer Cores

We coat your old cores with a new covering and can also remove the old covering beforehand if required. If necessary, we can create new custom molds.

Coating of new Customer Cores

We can also coat the new cores you provide us with. If there are already existing custom molds, we use these, otherwise we produce new molds to suit.

Coating of Gate Rollers

For some applications, it is necessary to coat the running surface so that, for example, the steel roller does not run on a steel rail on gates.

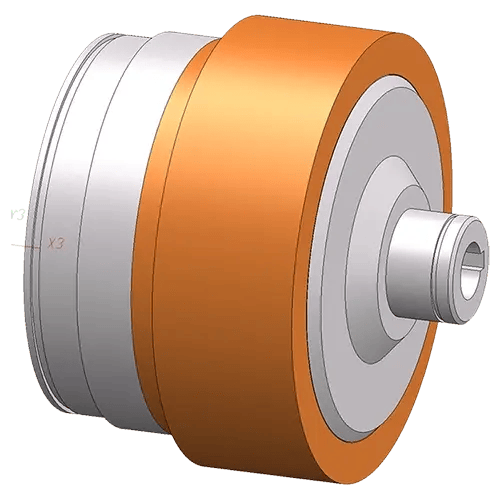

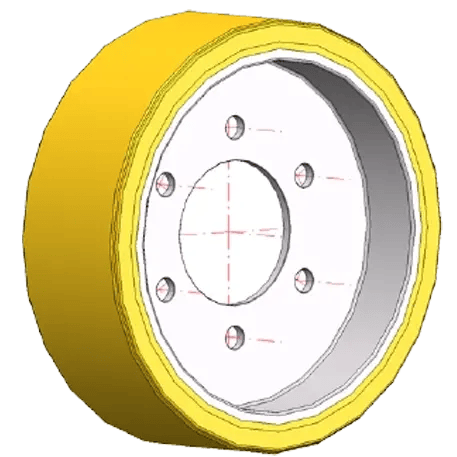

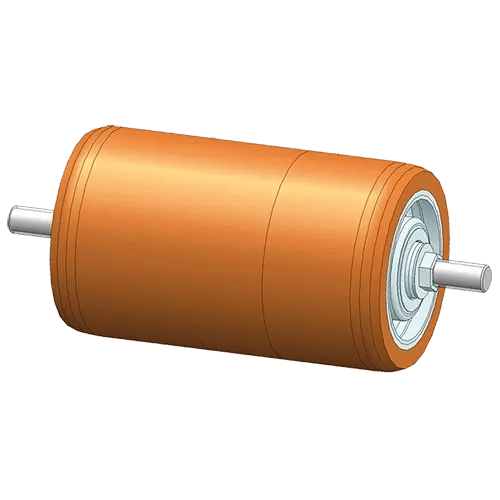

Drive Wheels, individually coated

Re-coating used drive wheels as well as manufacturing completely new drive wheels to customer specifications does not present us with any particular challenges.

Coatings with Special Contours

Special contours can also be realized with our coatings at the customer's request.

Antistatic Coating with Cross-Country Tread

For a customer in Canada, we manufactured drive wheels with a steel core and antistatic coating including an off-road profile and gained a satisfied customer.

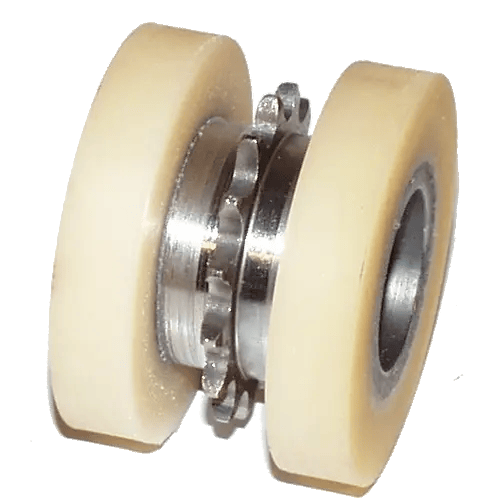

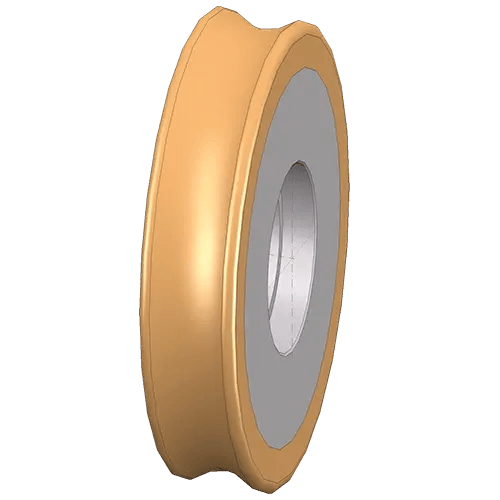

Coatings with Round Groove

Some elevator pulleys, cable pulleys or door rollers require a round groove. We can also produce this on request.

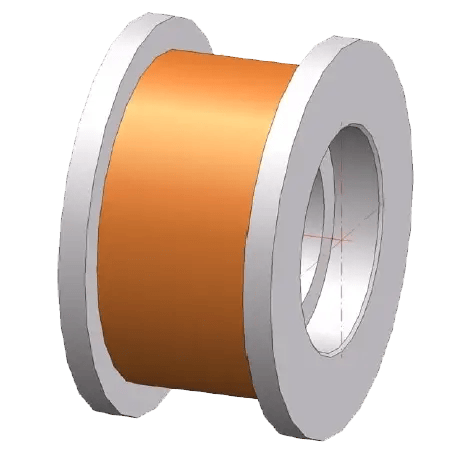

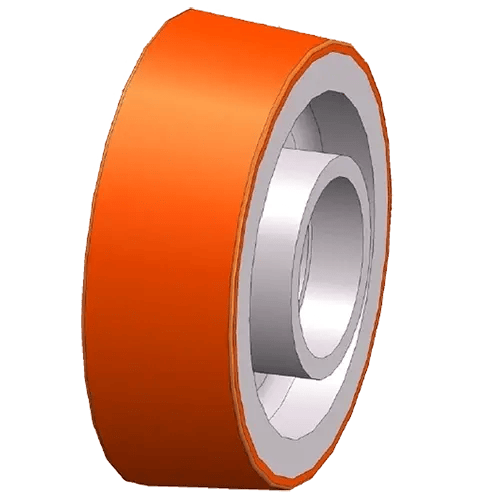

Flanged Wheels with Coating

We also repeatedly coat flanged wheels, which usually run on steel rails, with different materials and shore hardnesses.

Sloped Coatings

For some applications it may be necessary to coat an inclined running surface. We can do this, just ask us.

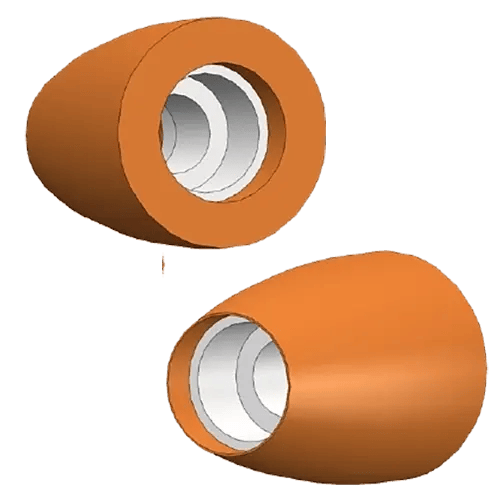

Conical and Round Coatings

For this particular customer, we manufactured conical rollers with special radii that were not available anywhere else.

Thin-walled coatings

These special castors for a German manufacturer of luxury motorhomes are a particular challenge due to the very thin coating on a stainless steel tube.

Coated Conveyor Rollers

We either coat conveyor rollers, rollers and idlers directly onto the core or press Vulkollan® pipe sections onto them. This protects the conveyed goods and reduces rolling noise.

You might also be interested in this ...

Direct contact with the design department?

Do you need individual advice and would like to speak directly to our design engineers?

Then send them an e-mail or call them directly.

Rolling in the right direction: Our Technical Guide

Find the ideal wheels and castors or conveyor technology components for your requirements and projects - with helpful tips concerning selection criteria, surfaces, load capacity an much more.

Get in touch with us

Do you have any questions or requests? You can send us an inquiry using our form and we will get back to you as soon as possible.

Or do you have any questions and need advice by phone? Please give us a call.

Individual coatings for wheels and wheel cores with Vulkollan® and polyurethane at Schwalb Rollen

At Schwalb Rollen, we are experts in customized coatings for wheels and wheel cores. Our high-quality solutions with Vulkollan® and polyurethane offer an optimum combination of durability, resilience and flexibility - ideal for industrial applications where maximum precision and reliability are required.

Why individual coatings?

Our individual coatings are specially tailored to your requirements. Whether for use in harsh environments, with high loads or in extreme temperatures - we offer the right solution. Wheels coated with Vulkollan® and polyurethane are characterized by excellent wear resistance, high load-bearing capacity and a long service life. These materials also offer excellent shock absorption and quiet running, making them ideal for use in a wide range of industrial applications.

Vulkollan®: The ultimate for high-performance applications

Vulkollan® is a high-performance polyurethane characterized by extreme resilience and elasticity. It is particularly suitable for applications involving high dynamic loads and offers outstanding resistance to abrasion, oils and chemicals. Wheels with Vulkollan® coatings from Schwalb castors are the perfect choice for demanding operating conditions.

Polyurethane: Versatile and robust

Polyurethane is known for its versatility and is often used in applications that require both flexibility and stability. It offers excellent resistance to abrasion, impact and wear, making it ideal for coating wheels and wheel cores. Polyurethane wheels from Schwalb castors are particularly durable and suitable for a wide range of industrial applications.

Why Schwalb castors?

At Schwalb castors, we focus on quality and precision. Our individual consultation and production ensures that you receive the exact coating that meets your specific requirements. With our many years of experience and technical expertise, we are your reliable partner.

Contact us for your individual solution

Would you like to find out more about our individual coatings with Vulkollan® or polyurethane? Get in touch with us today! The Schwalb Rollen team is at your disposal to discuss your requirements and offer you a customized solution.

Conclusion

Rely on Schwalb Rollen's expertise for your individual coatings for wheels and wheel cores. With our high-quality Vulkollan® and polyurethane materials, we ensure that your wheels always function reliably, even under the most demanding conditions.

Schwalb Rollen - your partner for durable, resilient and precisely coated wheels!